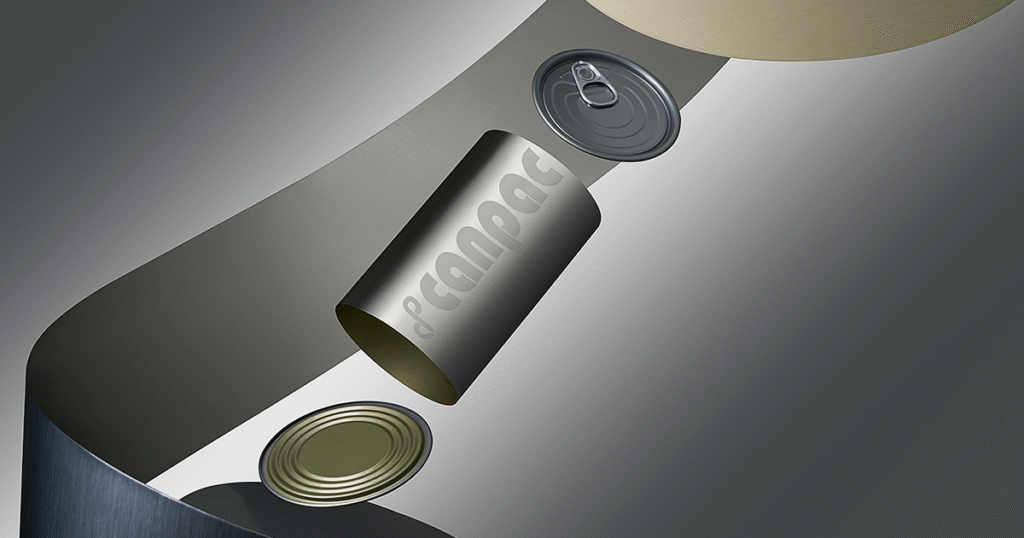

A 3-piece can is a widely used metal packaging solution consisting of three separate components: the body, top, and bottom. This design allows for strong durability, secure sealing, and customizable branding, making it ideal for food, beverage, and industrial applications.

Structure and Manufacturing Process

The body of a 3-piece can is typically formed from a flat sheet of metal, rolled into a cylindrical shape, and sealed with a side seam. The top and bottom are separately manufactured and attached through an end-seaming process, ensuring a leak-proof seal. This construction method provides flexibility in size and shape, making it suitable for various industries.

Advantages of 3-Piece Cans

- Durability: Made from tinplate or aluminum, these cans offer high resistance to external damage.

- Extended Shelf Life: The airtight seal prevents contamination and preserves the contents for a longer period.

- Customization: The separate components allow for varied designs, embossing, and printing, enhancing brand visibility.

- Versatility: Used in food packaging, aerosol sprays, and industrial storage, adapting to different needs.

Applications of 3-Piece Cans

- Food Industry: Commonly used for canned vegetables, soups, and seafood, ensuring freshness and quality.

- Beverage Packaging: Some carbonated drinks and specialty beverages utilize 3-piece cans for secure containment.

- Aerosol Products: Found in spray paints, deodorants, and insect repellents, benefiting from the pressurized design.

- Industrial Use: Used for chemical storage, lubricants, and adhesives, offering strong protection.

Comparison with 2-Piece Cans

While 2-piece cans are formed from a single sheet, eliminating the side seam, 3-piece cans provide greater flexibility in size and shape. The additional seam may slightly increase material usage, but the customization options make them a preferred choice for varied applications.

Sustainability and Recycling

3-piece cans are highly recyclable, contributing to eco-friendly packaging solutions. The use of tinplate and aluminum ensures minimal environmental impact, making them a sustainable choice for manufacturers.